What's the type of cutting?

Laser cutting is often used in industrial manufacturing areas for cutting sheet metal and pipes, ano other materials also, using the smart computer controls high output laser to do the cutting.

Plasma cutting uses a torch which lows an inert gas at high speed through a nozzle which when held close enough to parts creaste an arc and melts the material.

Water jet cutting uses extramely high pressure and velocity water to cut into metals, A torch is used in oxyfuel cutting to heat the metal, oxygen is then blown into the part causing the metal that it combines itself with to leave the cut as slag.

Electric discharge(EDM) is also known as park machining or spaking eroding. EDM removed material by rapid arc discharges between the electrode of the cutter and the work-piece which has to be a conductor

What is laser cutting?

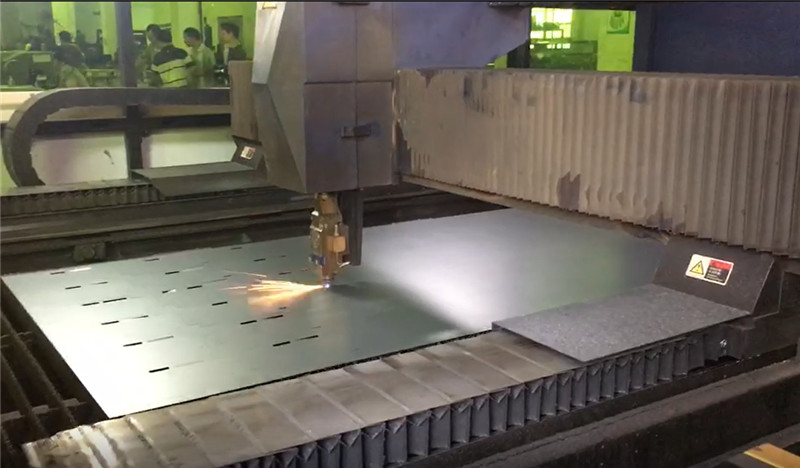

Laser cutting, is the process of cutting the material using the laser beam, this can be done either trim down a material or to help cutting into complex shapes in flat, this process also has similarities to the laser drilling and laser engraving process. The former involves the creation of thru-holes in a material or dents, like an engraving used in the following process, these dents and holes are essentially cuts, and you will often see a laser cutting machine being used for laser drilling and laser engraving too, A vast range of materials and thickness sizes can be cut using laser cutting, and making it a handy and adaptable process.

How it works?

The laser cutting process works by having a focused precise laser beam running through the material, and delivering an accurate and smooth finishing, initially, the laser is used to pierce the material with a hole at edge, and the beam is continued along from there

Why choosing laser cutting compared to CNC Machining?

Laser cutting has low maintenance costs and only needs inexpensive replacement parts

The laser cutting process helps to dramatically reduce material wastage

One laser cutting setip is capable of working with multiple materials

It is much safer using laser cutting than other processes as the beam is enclosed withing a light box

Due to its low cost and high efficientcy, laser cutting is a widely used for rapid prototyping and low volume manufacturing, or even large quantity production.

If you have some sheet metal parts to need do, welcome to contact with YSY.

Key Products

● Alminium box

● Power supply bracket

● Electronic aluminium case

● Laser cutting metal

● Auto moto parts

● Metal Box

● Electrical Box

● Aluminum amplifier chassis

● Display racks

● Control panel enclosure

● Instrument case

● Aluminum laser cutting

● Aluminum Enclosure

● Distribution Box

● Studio rack mount

● Metal poles

● Control panel

● Laser cut service

● Electrical enclosures

● Power Supply Enclosure

● Sheet Metal Enclosure

Post time: Jul-05-2022