The use of aluminum extrusion in product design and manufacturing has increased significantly in recent decades. According to a recent report from Technavio, between 2019-2023 the growth of the global aluminum extrusion market will be accelerating with a Compound Annual Growth Rate (CAGR) of almost 4%, here is the short instruction of what aluminum extrusion is, the benefits it offers, and the steps involved in the extrusion process.

What is Aluminum Extrusion?

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comes out in the same shape as the die and is pulled out along a runout table. At a fundamental level, the process of aluminum extrusion is relatively simple to understand. The force applied can be likened to the force you apply when squeezing a tube of toothpaste with your fingers.

As you squeeze, the toothpaste emerges in the shape of the tube’s opening. The opening of the toothpaste tube essentially serves the same function as an extrusion die. Since the opening is a solid circle, the toothpaste will come out as a long solid extrusion.

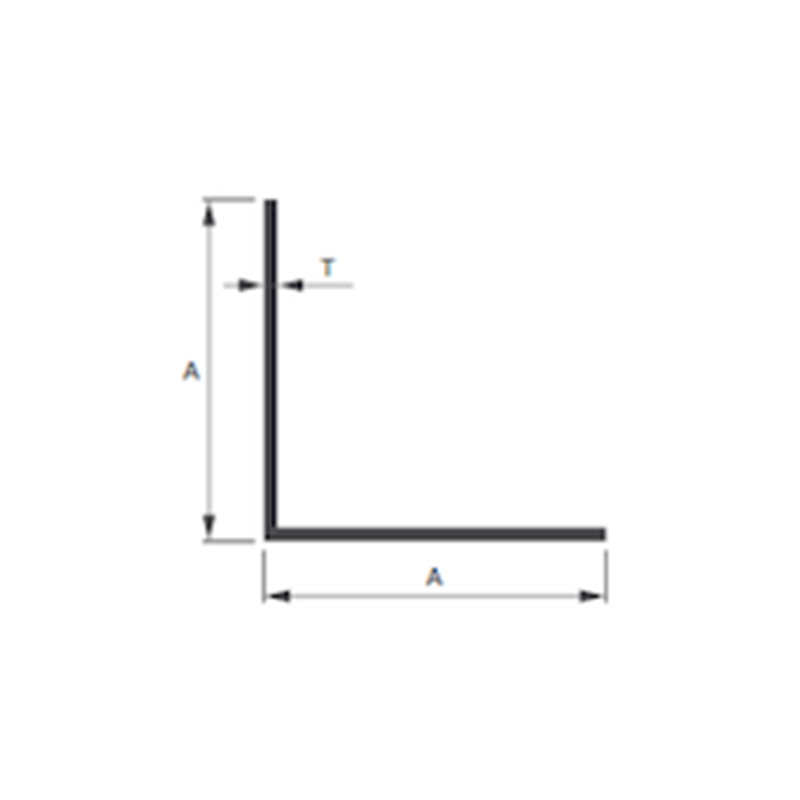

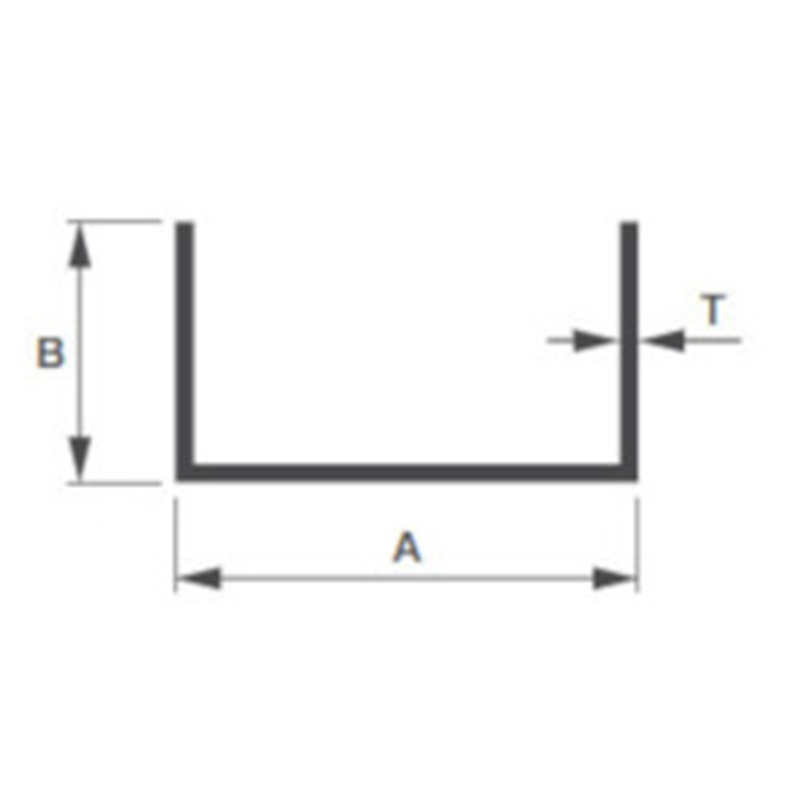

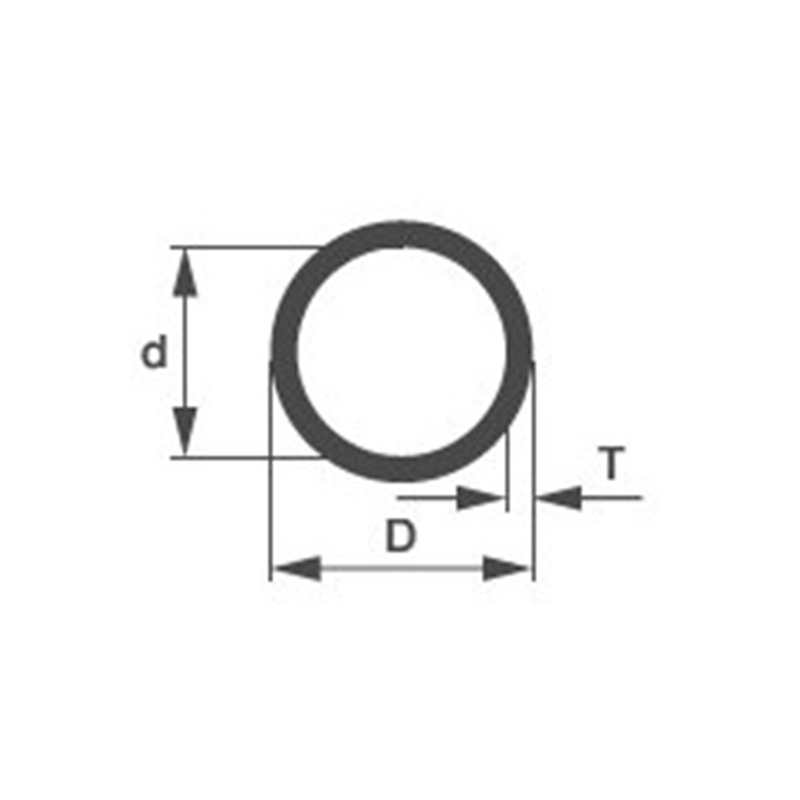

Here are some examples of the most commonly extruded shapes: angles, channels, and round tubes.

On left are the drawings used to create the dies and on the right are renderings of what the finished aluminum profiles will look like.

Drawing: Aluminum Angle

Drawing: Aluminum Channel

Drawing: Round Tube

Normally, there are three main categories of extruded shapes:

1. Solid, with no enclosed voids or openings (i.e. a rod, beam, or angle).

2. Hollow, with one or more voids (i.e. square or rectangular tube)

3. Semi-hollow, with a partially enclosed void (i.e. a “C” channel with a narrow gap)

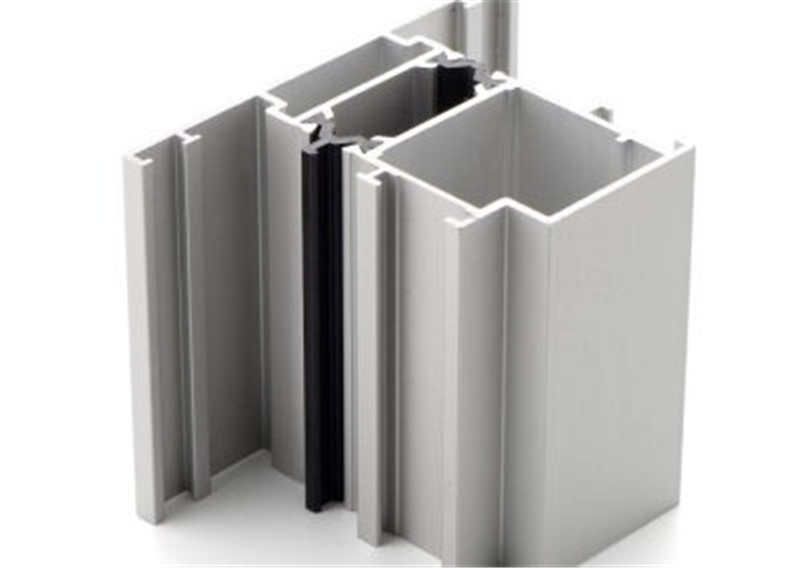

Extrusion has innumerable applications across many different industries, including the architectural, automotive, electronics, aerospace, energy, and other industries.

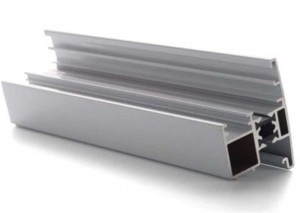

Below are some examples of more complex shapes that were designed for the architectural industry.

The Aluminum Extrusion Process in 10 Steps

Step #1: The Extrusion Die is Prepared and Moved to the Extrusion Press

Step #2: An Aluminum Billet is Preheated Before Extrusion

Step #3: The Billet is Transferred to the Extrusion Press

Step #4: The Ram Pushes the Billet Material into the Container

Step #5: The Extruded Material Emerges Through the Die

Step #6: Extrusions are Guided Along the Runout Table and Quenched

Step #7: Extrusions are Sheared to Table Length

Step #8: Extrusions are Cooled to Room Temperature

Step #9: Extrusions are Moved to the Stretcher and Stretched into Alignment

Step #10: Extrusions are Moved to the Finish Saw and Cut to Length

Once extrusion is completed, profiles can be heat treated to enhance their properties.

Then, after heat treatment, they can receive various surface finishes to enhance their appearance and corrosion protection. They can also undergo fabrication operations to bring them to their final dimensions.

Heat Treatment: Improving Mechanical Properties

Alloys in the 2000, 6000, and 7000 series can be heat treated to enhance their ultimate tensile strength and yield stress.

To achieve these enhancements, profiles are put into ovens where their aging process is accelerated and they are brought to the T5 or T6 tempers.

How do their properties change? As an example, untreated 6061 aluminum (T4) has a tensile strength of 241 MPa (35000 psi). Heat-treated 6061 aluminum (T6) has a tensile strength of 310 MPa (45000 psi).

It is important for the customer to understand the strength needs of their project to ensure the right choice of alloy and temper.

After heat treating, profiles can also be finished.

Surface Finishing: Enhancing Appearance and Corrosion Protection

Extrusions can be finished and fabricated in various ways

The two main reasons to consider these is that they can enhance the appearance of the aluminum and can also enhance its corrosion properties. But there are other benefits as well.

For example, the process of anodization thickens the metal’s naturally-occurring oxide layer, improving its corrosion resistance and also making the metal more resistant to wear, improving surface emissivity, and providing a porous surface that can accept different colored dyes.

Other finishing processes such as painting, powder coating, sandblasting, and sublimation (to create a wood look), can be undergone as well.

In addition, there are many fabrication options for extrusions.

Fabrication: Achieving Final Dimensions

Fabrication options allow you to achieve the final dimensions that you are looking for in your extrusions.

Profiles can be punched, drilled, machined, cut, etc. to match your specifications.

For example, the fins on extruded aluminum heatsinks can be cross machined to create a pin design, or screw holes can be drilled into a structural piece.

Regardless of your requirements, there is a wide range of operations that can be performed on aluminum profiles to create the perfect fit for your project.

Aluminum Extrusion is an Important Manufacturing Process If you need to learn more about how to optimize your part design for the extrusion process, pls feel free to contact with YSY sales and engineering teams, we are ready for you anytime you need.

Post time: Jul-05-2022