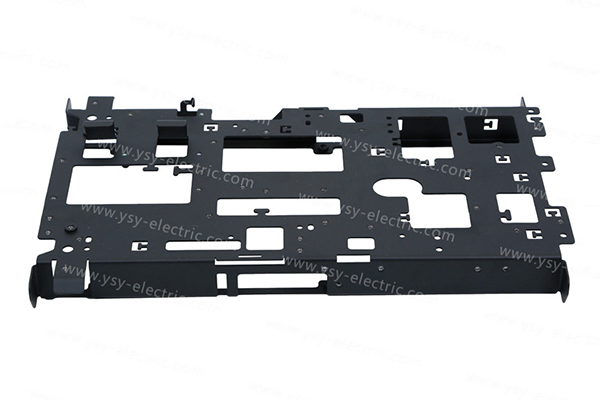

Quality Inspection for Power Shell - Punching Bending Metal Steel Laser Cuting Service – YSY

Quality Inspection for Power Shell - Punching Bending Metal Steel Laser Cuting Service – YSY Detail:

| Laser cutting capability | |

| Material | Galvanised steel, mild steel , stainless steel, aluminum alloy; brass alloy; tinplate, copper , Aluminum Alloy, Zink Alloy, Copper Alloy ect. (according to customer’s requirements for special material) |

| Surface Treatment | Galvanized (zinc-plated, nickel-plated, chrome-plated, silver-plated), |

| powder coating/oil painting, polishing (mirror polishing, electrolytic polishing), | |

| brushing, sand blasting, anodizing etc | |

| Flatbed Laser Cutting | Trumpf Flat Panel Fiber Laser Create parts accurately and quickly Cutting and etching in the same step From a single prototype to a full run Cutting steel, stainless steel, aluminum, copper, brass, etc. |

| Tube Laser Cutting | BLM 3D Tube Laser 3D rotating laser head Cut, chamfer, countersink and chamfer in one step Cutting tubes, channels, angles, square and open profiles From a single prototype to a full run Cutting steel, stainless steel and aluminum |

| water jet cutting | Techni water fountain Make parts out of very thick metal Water-based cutting methods do not heat the material From a single prototype to a full run Cuts all types of metal as well as granite, glass, stone, rubber and more |

| Plasma and oxy-fuel cutting | Bekal plasma cutting table High Definition Plasma and Oxy Fuel Cutting Rotary plasma head can bevel and cut complex geometries Integrated CNC multi-station for drilling, tapping, countersinking, etc. Cutting flat, tube and billet From a single prototype to a full run Cutting steel, stainless steel and aluminum |

| Laser cutting advantages | Cutting of Different Material Types and Thicknesses Extreme Precision Precise Energy Input Shorter Work Time Contact Free, Force-Free Processing Minimal Thermal Material Effort Kerfs of a Few Mircrometers are Possible |

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for Quality Inspection for Power Shell - Punching Bending Metal Steel Laser Cuting Service – YSY , The product will supply to all over the world, such as: Milan, Norwegian, Holland, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.