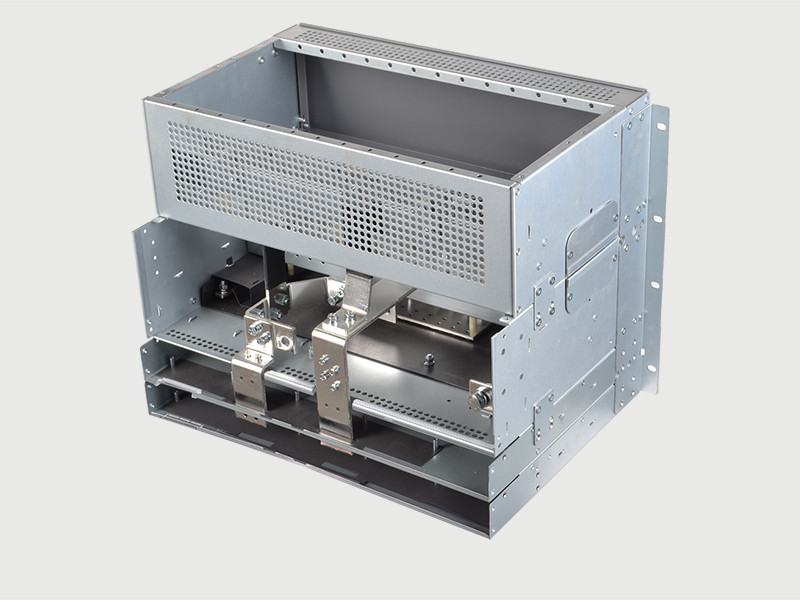

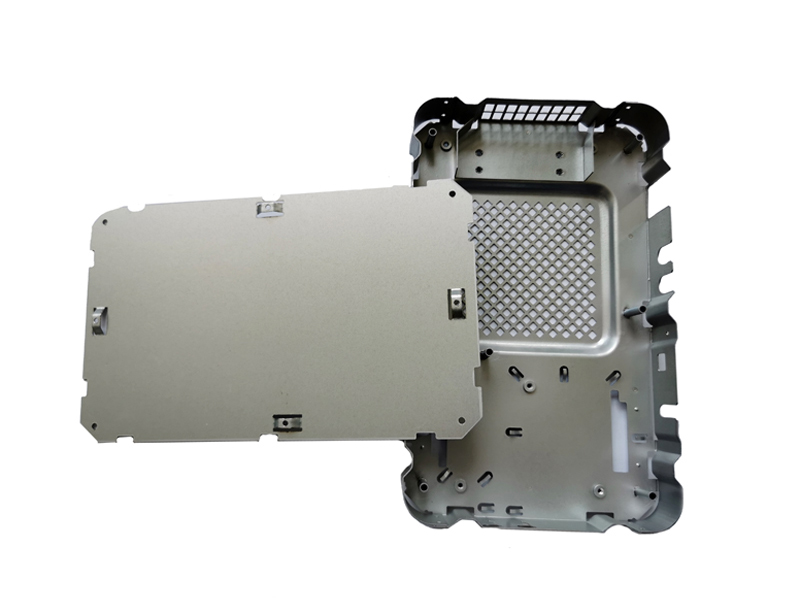

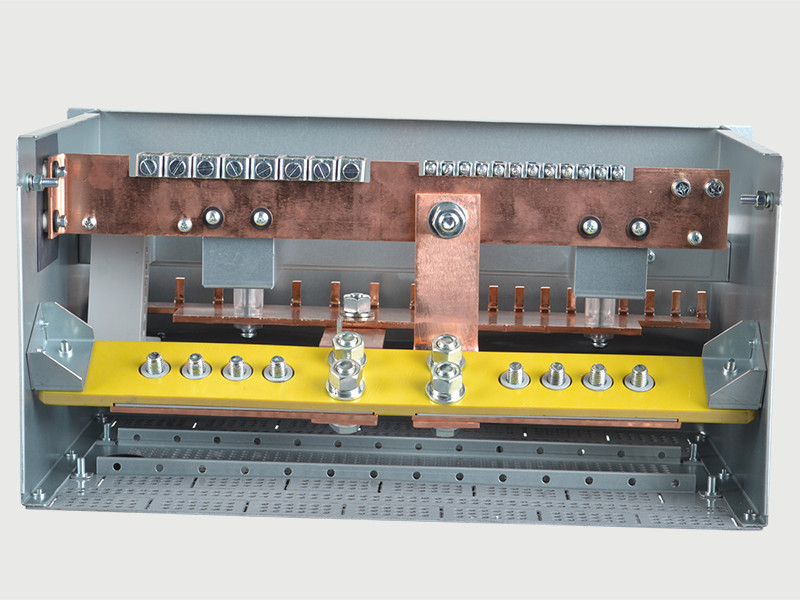

YSY not only focus on the production, and also have full experience to do the testing and assembly job for the parts, we have professional teams, including engineers, workers, equipment and line for the assembly, YSY’s aim is to help our clients to reduce the shipping space, save the labor cost for assembly, and also do the simple testing and checking, including tolerance matching, hole size and position, surface finishing, and the testing of whole structures, as well as assembly for prototype and mass production, YSY will work tightly with customers to control the quality strictly, and optimize the procedure of assembly and save the production and labor cost, win together with our partners.

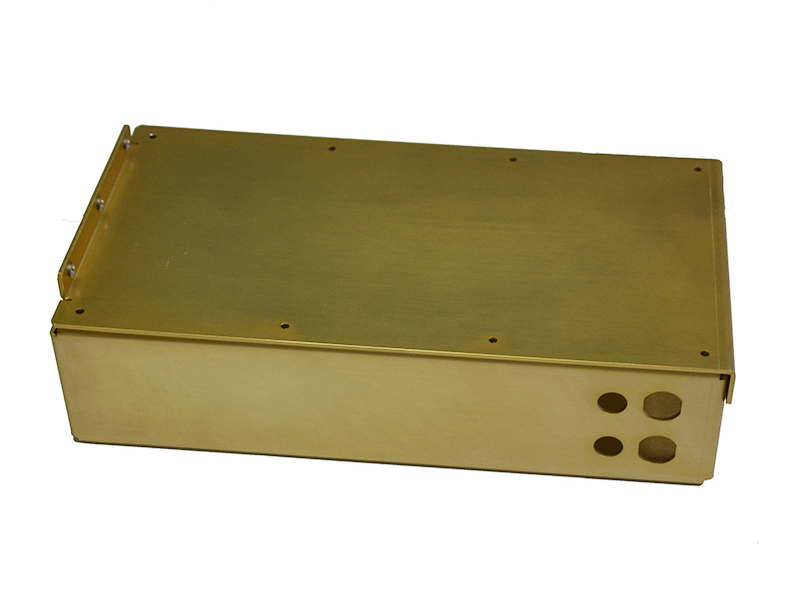

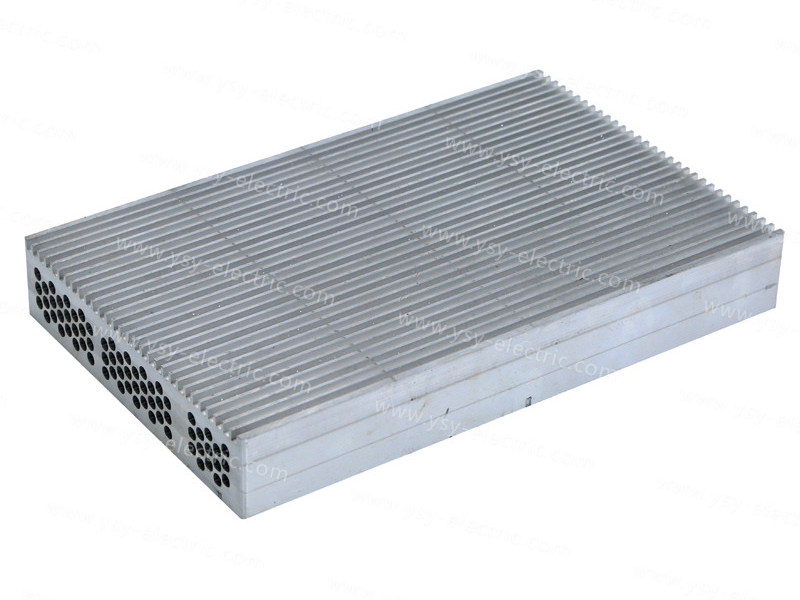

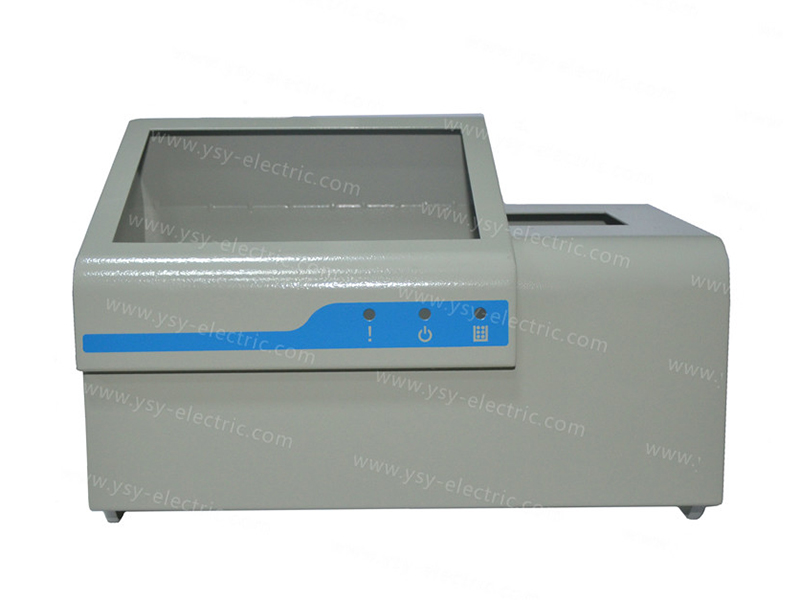

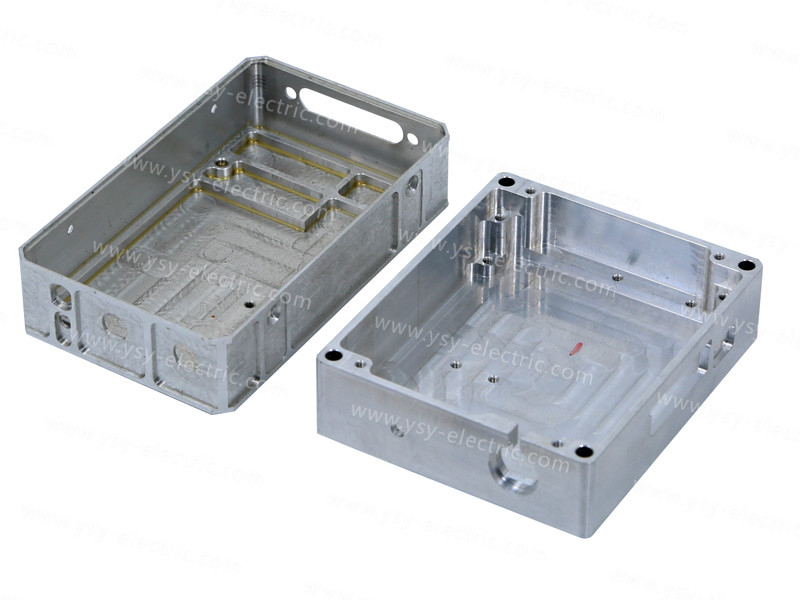

The parts are widely used on metal casing and housing, electrical box, new energy battery box, Self-Service machine, medical equipment, EV Charger, Solar energy system and other chassis and frame.

The main future of the production:

1.Different raw material options, including stainless steel, SPCC, aluminium, Zinc plates, SGCC etc

2.Different surface treatment options, including power coating, E-plating, brush, nature, galvanized etc

3.OEM and ODM design support. YSY has its own engineering and design team, can provide both OEM and ODM services, help the partners to control the production cost as well as the quality.

4.Quick response and professional manufacture capacity as well as trading service, build good relationship with partners for long term cooperation.

5.Professional assembly ability to help partners to full set of the products in China, provide one-station service

Welcome to contact with YSY team!

Post time: Dec-19-2022