Manufacturer for Aluminium Welded Frames - Custom Made Sheet Metal Stamping Bending Parts – YSY

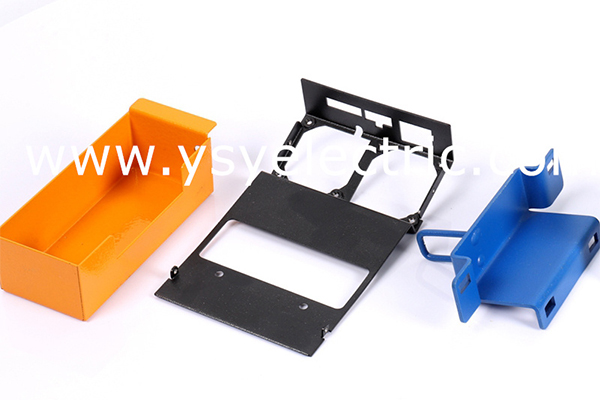

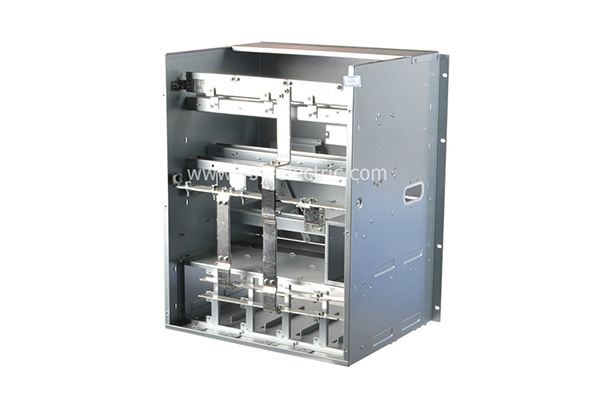

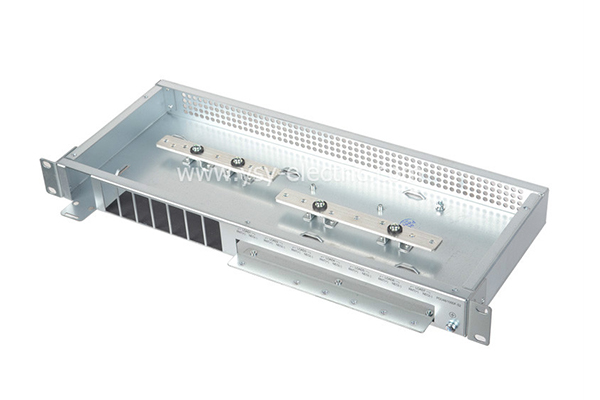

Manufacturer for Aluminium Welded Frames - Custom Made Sheet Metal Stamping Bending Parts – YSY Detail:

Metal Stamping Production Methods

Several different production features can be implemented depending on part geometry and requirements. The below terms describe some of the more common stamping methods.

Compound Die

The composite tool performs multiple steps simultaneously to cut and shape the metal in one pass. This manufacturing process is faster than a multi-stage stamping and forming system that requires multiple manual operations or movements.

Progressive Die

Progressive stamping dies use multiple stations in the same tool to incrementally modify parts in a series of steps. Progressive tooling enables manufacturers to process plates or blanks into highly complex three-dimensional products without stress or damage to the metal. To this end, continuous strips of material are introduced into the tool through different stations until the finished product is ejected from the last station. Using this controller, the high-speed automation of the production line can be realized, allowing continuous stamping operation and 1000 pieces per hour.

Shenzhen YSY Electric Equipment Co., Ltd.

Founded in 2008 as sheet metal workshop in Shenzhen, after more than 10 years developmentand improvment. Now we are a ultimate one-stop shop for custom made electrical equipments and custom metallic components with ISO 9001:2015 certificate. The company starts to do foreign trade on 2010, now almost 70% partners come from all over the world.The producing center is occupied more than 5000 sqm, we have the production team with 200 people, including 10 engineers and QC team.

Our equipment includes laser cutting machine, AMADA and TAILIFT numerical control press, NC bender, and we own two different assemblye line with all automatism. Our customers, are from the whole world already cooperated with us for years. We accommodate customers’ requirement of OEM&ODM design.

Our products, including electric enclosures, such as control boxes, distribution boxes etc, electrical custom components and precision cnc machinery parts, are widely used in communication, in the construction of national infrastructure, monitoring system, Auto and engineering projects from the whole wide world.

The entire computerized technical design, advanced management and the dedicated specialist as well as the precise manufacturing procedure, provides the high quality products for our customers. Quality is the number 1. Objective to our factory and the guide for our production.

We welcome the customers from whole world come to visit us, and your appreciation would be the blue ribbon to us for forever.

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Manufacturer for Aluminium Welded Frames - Custom Made Sheet Metal Stamping Bending Parts – YSY , The product will supply to all over the world, such as: Anguilla, Germany, Philippines, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.